Transforming Jewelry Polishing: Reliable Motor Solutions for Modern Demands #

In the evolving landscape of jewelry manufacturing, achieving consistent quality and operational efficiency is paramount. As the industry seeks advanced solutions for polishing applications, the focus turns to high-performance, customized motors that address common challenges such as unstable speeds, overheating, and high maintenance costs.

Addressing Key Challenges in Jewelry Polishing #

Unstable Speed #

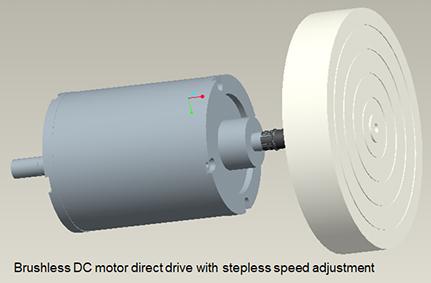

During jewelry processing, fluctuations in speed—often caused by high slip in traditional belt-driven systems—can negatively impact polishing time and surface finish. This not only affects product quality but also accelerates belt wear and increases the risk of motor failure. To overcome these issues, we implement high-efficiency direct-drive permanent magnet brushless DC motors, replacing conventional induction motors with belt pulley structures. This approach ensures stable speeds, leveraging the motor’s low-speed, high-torque, and low-temperature rise characteristics. Our specialized controllers maintain synchronized speeds, delivering consistent polishing results regardless of gemstone hardness, and enhancing both precision and repeatability.

Overheating Issues #

Standard motors operating for extended periods are prone to overheating, which can shorten their lifespan and degrade performance. By thoroughly evaluating motor specifications and mechanical structures, we utilize computer-assisted simulations to optimize both performance and temperature profiles. Adjustments to silicon steel sheet dimensions, magnet demagnetization temperatures, and copper wire gauges ensure the motor can withstand prolonged operational loads. Our patented natural cooling technology, integrated into a unique driver, effectively manages temperature rise, prevents overheating, and extends motor lifespan while maintaining optimal performance.

High Maintenance Costs #

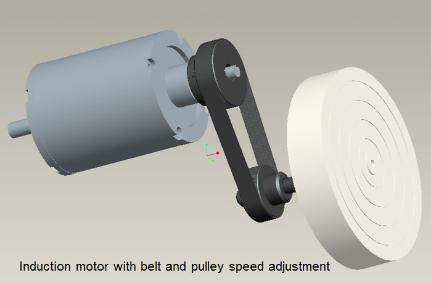

Traditional motors with belt-driven pulleys often encounter belt wear, noise, and overheating, leading to increased maintenance requirements and costs. Our direct-drive built-in spindle synchronous servo motors eliminate these issues by removing belt dependencies, resulting in smoother and more reliable operation. The compact design reduces machine size, noise, and weight, while built-in protection mechanisms detect overload, overheating, overspeed, and improper operation, minimizing failure rates and reducing long-term operational expenses.

Success Stories and Measurable Improvements #

Clients utilizing our customized motor solutions have reported significant gains in processing efficiency and product quality. Polishing times have been reduced by 30%, and product pass rates have increased to 95%.

Comprehensive System Optimization #

Beyond supplying high-efficiency motors, we optimize the overall mechanical design to minimize wear on other components and enhance system efficiency.

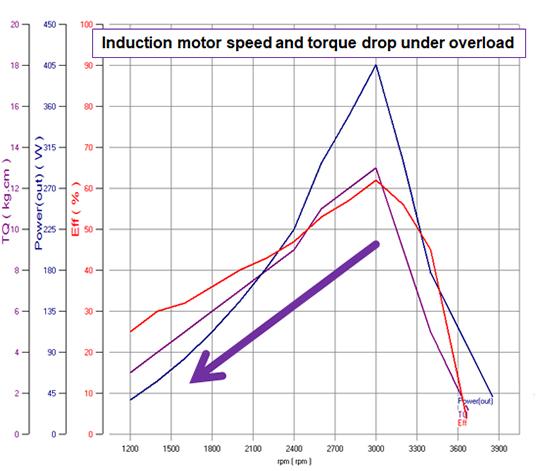

Traditional polishing machines typically rely on induction motors with belt pulleys to drive wheels or belts. Under rough grinding conditions, these pulleys are susceptible to slippage and severe wear, resulting in unstable speeds and excessive material consumption or uneven surfaces. The TN curve of induction motors shows that during heavy loads, both speed and torque decrease, forcing technicians to constantly adjust their force, which disrupts process stability and complicates standardization.

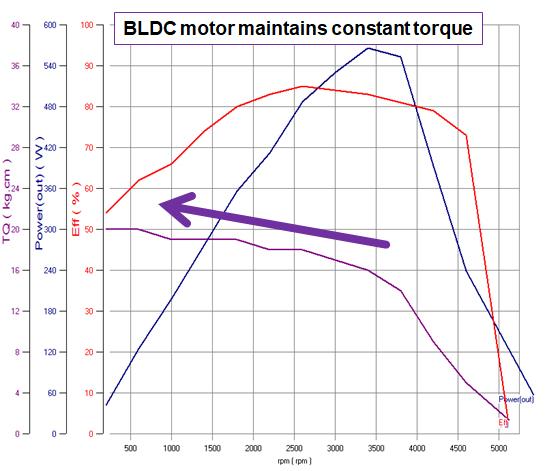

By adopting brushless DC motors (BLDC) for direct drive, we eliminate instability caused by belt pulleys and the need for frequent belt replacement. The load-speed feedback control mechanism of BLDC motor controllers maintains stable speeds and nearly constant torque, even under heavy loads. This ensures consistent processing conditions, reduces reliance on operator experience, and supports the establishment of standardized operating procedures (SOPs). As a result, machine stability is significantly improved, and operator-induced material wastage is minimized.

With enhanced mechanical performance, semi-automated production becomes feasible, boosting output and transforming the diamond polishing industry from labor-intensive to technology-driven. This shift reduces personnel management uncertainties and effectively lowers labor costs, paving the way for industry upgrades.

Technical Support and Training #

We offer comprehensive technical support and training to help clients fully leverage the capabilities of our products.

Tailored Solutions for Your Needs #

For those seeking customized motors or specialized solutions, our professional team is ready to assist with tailored designs and detailed service information. Contact us to explore the best solutions for your jewelry polishing applications.